Exothermic Welding Tools

INDUSTRIES

WELD PREPARATION KIT

Exothermic welding requires thorough preparation, including cleaning conductors with wire brushes, molds with soft brushes, and scraping the crucible. Exar Industries UK Ltd. offers a preparation kit that includes all necessary tools, including a flint ignition gun.

Exothermic welding requires thorough preparation, including cleaning conductors with wire brushes, molds with soft brushes, and scraping the crucible. Exar Industries UK Ltd. offers a preparation kit that includes all necessary tools, including a flint ignition gun.

BLOW TORCH

Graphite molds for exothermic welding must be heated with a blowtorch to remove absorbed moisture, even if they feel dry. Proper heating ensures effective welding, as unprepared molds may compromise the weld's quality in the Exar Weld process.

Graphite molds for exothermic welding must be heated with a blowtorch to remove absorbed moisture, even if they feel dry. Proper heating ensures effective welding, as unprepared molds may compromise the weld's quality in the Exar Weld process.

SAFETY GLOVES

Although the Exar Industries Weld system minimizes heat exposure, users are advised to wear protective safety gloves to ensure hand safety during the welding process.

Although the Exar Industries Weld system minimizes heat exposure, users are advised to wear protective safety gloves to ensure hand safety during the welding process.

MOULD SEALER

Sealers are used to pack around conductors during exothermic welding, though typically unnecessary. For repeated mold use, sealing prevents molten metal leakage and air access to the crucible, ensuring a more effcient welding process.

Sealers are used to pack around conductors during exothermic welding, though typically unnecessary. For repeated mold use, sealing prevents molten metal leakage and air access to the crucible, ensuring a more effcient welding process.

WELDING POWDER

Exothermic welding powder, typically a mixture of metal oxide and aluminum, initiates a chemical reaction that generates extreme heat. This molten metal flows into the mold, bonding conductors with a durable, electrically conductive joint, ensuring a strong, permanent connection.

Exothermic welding powder, typically a mixture of metal oxide and aluminum, initiates a chemical reaction that generates extreme heat. This molten metal flows into the mold, bonding conductors with a durable, electrically conductive joint, ensuring a strong, permanent connection.

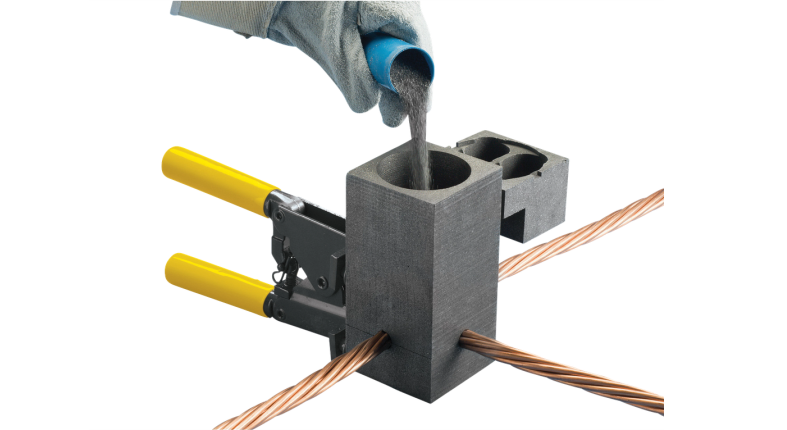

MOULDS, HANDLE CLAMPS AND JOINT TYPES

The joint type determines the required mold, and the mold shape dictates the handle clamp type.

The joint type determines the required mold, and the mold shape dictates the handle clamp type.

Download